Data Science

The Challenge

The “Smart Factory” plays a major role in the future project Industry 4. 0. It describes the vision of self-organizing manufacturing facilities. Already today, robots are being used throughout the automotive industry. In the course of production, malfunctions occur time and again that lead to downtimes or even production stoppages. Unexpected and unnecessary additional costs and delivery delays are the result. Static maintenance at fixed intervals only helps to a limited extent and leads to further unnecessary downtimes and consumption of spare parts. Therefore, our customer was looking for a software solution to minimize future failures and time losses in its production for car bodies. This solution should analyze the behavior of the welding robots used as automatically as possible in order to be able to detect and predict faults at an early stage (predictive maintenance).

- Application case

Automotive

- Target setting

- Avoiding downtime

- Maintenance on demand

- tasks

- Synchronizing and harmonizing data over time

- Automatic recording of the behavior patterns for each robot

- Modelling the interrelataionships

- Forecasting of failures

- Technologies

- R

- Hive

- Impala

- Spark

- Python

- Hadoop

The solution

Predictive maintenance is based on the analysis of historical plant data using statistical methods and advanced methods of machine learning. The mathematical models developed here are used to predict the future behavior of the system and help to identify critical plant conditions in good time.

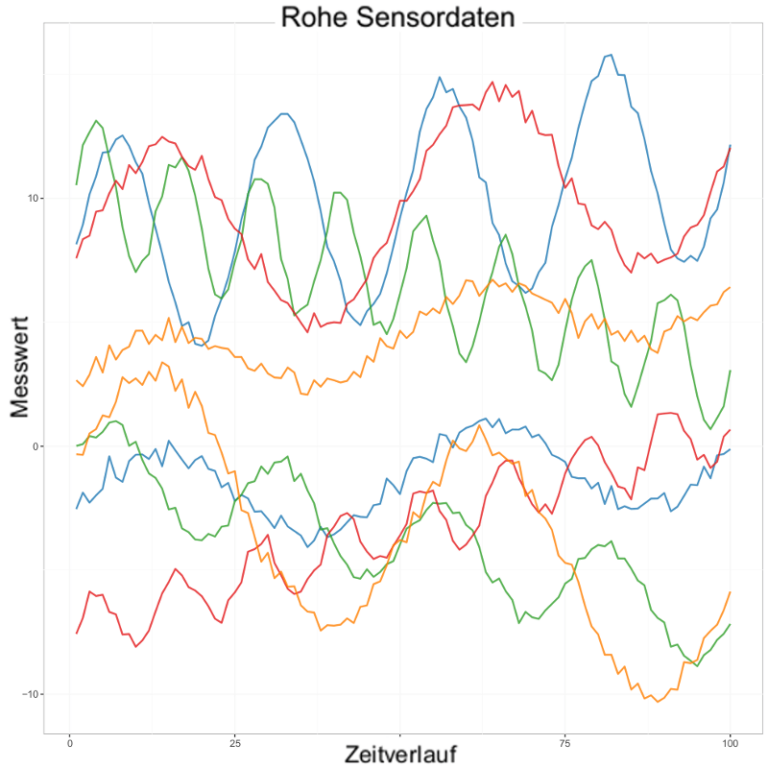

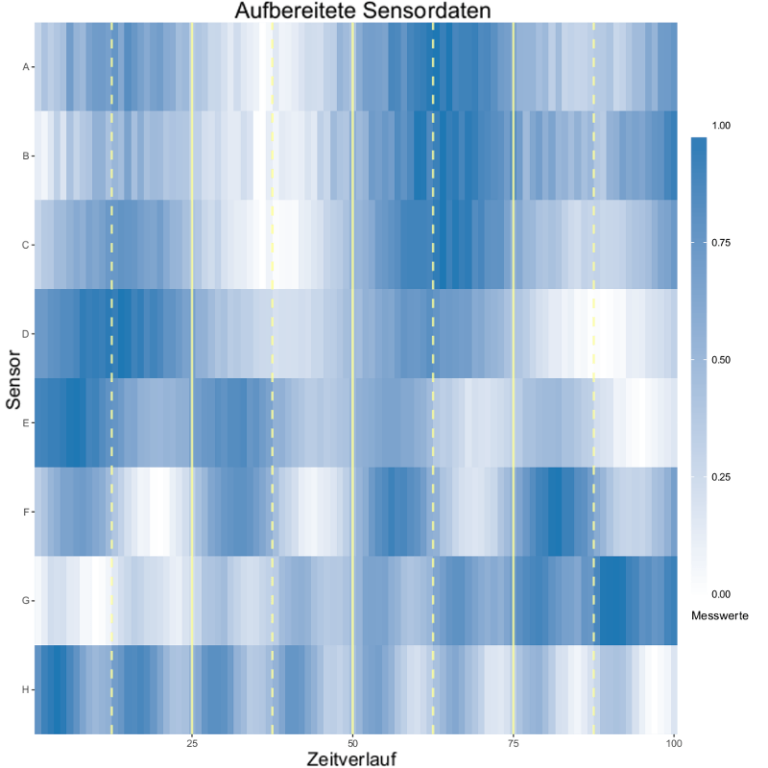

The basis was the creation of a temporally synchronous history of the status information and fault messages. Subsequently, the characteristic behavioral patterns of the individual production cycles of body manufacturing were identified and transferred to normalized states. Together with the department, practical misconduct was determined and the relevant production cycles examined for possible sources of error and dependencies. Using non-linear classification algorithms, the relationships between the behavior patterns and fault messages could be modeled within the production cycles. In the future, forecasts will be made regarding the probability of failure of individual devices and potential causes of failure will be investigated. The models were trained in a Hadoop cluster. Distributed processing with Spark will streamline and accelerate the analysis.

The result

A system has been developed to continuously analyze the behavior of industrial robots and connected components and to predict events in the future. Behavior models were used to create a kind of fingerprint for each robot. Based on prediction models make allow to determine the probability of failure of individual devices and production sections. The malfunctions predicted in this way are displayed to the customer. As a result, those responsible can intervene preventively even before a fault occurs. This not only avoids operational stoppages, but also reduces the consumption of wear and machine parts. This means that robot-based processes can be maintained in line with requirements and the causes of faults can be traced. This lowers production costs and leads to successive process optimization.

- Benefits

- Maintenance intervals as required

- Increased transparency of the technical connections

- Reduction of downtimes

- Reduction in the consumption of spare parts

- Minimization of unplanned production losses