Data Engineering

The Callenge

Infineon Technologies AG is one of the largest global suppliers of semiconductor- and system solutions in the fields of energy efficiency, mobility and security.

For its semiconductor production, Infineon produces semiconductor chips from silicon wafers for further processing. While passing through the production chain interferences may occur, which lead to defects on the chips. In the case of customer claims, the determination of error sources is rather complicated, due to the high number of resources and process steps involved.

The determination of which semiconductor was build in any intermediate or final product behaves similarly. Since the productive traceability of products as well as of individual components from the origin through to completion and vice versa, the so-called forward- and backward tracing, is not possible straightaway, necessary actions cannot always be conducted.

Within the context of a tender, Infineon has therefore sought for concepts to increase the transparency of the production process, which shall contribute to a better tracking of the semiconductor manufacturing and consequently also to a more proactive customer care

- Use Case

Semiconductor manufacturer

- Goal setting

- Transparency of all production stages

- Technologie

- Hadooop

- HBase

The Solution

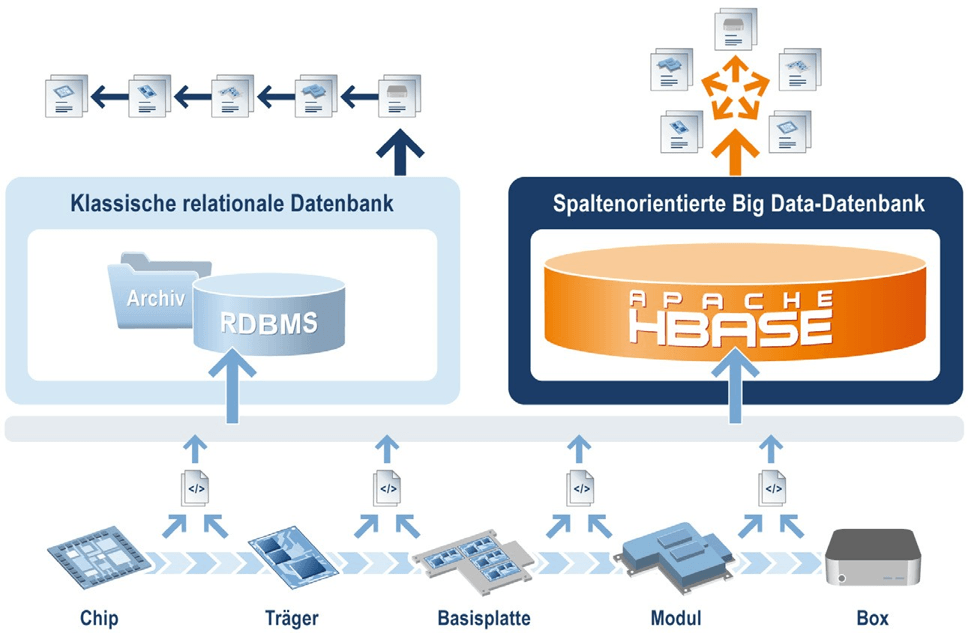

With the previous use of a classic relational database the capturing of the high number of production stages can be handled only on a limited level. Whereas the use of a column-oriented Big Data database will make it possible to store and process all the data of productions orders without restrictions. New options for the tracking of the production steps will be offered as well.

Infineon decided to build an Apache HBase database. This database will now archive all the data from the semiconductor production as well as their history on an optimized level and provide them to analysis systems. As a result, all the process steps involved and all the resources can be tracked up to the starting product (the chip) at any time. A web-based analysis front-end with various specialist search masks allows permanent access to the Big Data database.

The Result

The Big Data concept developed by TIQ Solutions was taken over by Infineon for the development of a prototype. An additional check by T-Systems Multimedia Solutions GmbH confirmed the efficiency of this solution as well. This Big Data concept enables Infineon to build a productive forward and backward tracing, which shall contribute to a faster and more straightforward error decoding. Due to the simplified traceability of the individual production stages internal and external sources of error can be clearly identified. Based on that, automatisms, which can prevent faulty semiconductor chips and will also allow a generalization of error patterns, can be developed. This prevents further processing of faulty chips and allows a customer and employee-friendly organization of complaints processes.

- Benefits

- Traceability of all production stages

- Faster error decoding

- Consumer satisfaction

- Support of the process automation

- Increased productivity

Graphics